A record that reframes the fusion race

Canada’s General Fusion has reported a new benchmark of roughly 600 million fusion neutrons per second, sharpening global attention on its magnetized target fusion approach. The milestone arrives from a campaign of plasma compression experiments designed to validate key physics at meaningful scale. While not yet a net-energy device, the result strengthens confidence in a pathway toward practical, pulsed fusion power. It also underscores how a clever blend of mechanical compression and magnetic confinement may sidestep some of fusion’s toughest roadblocks.

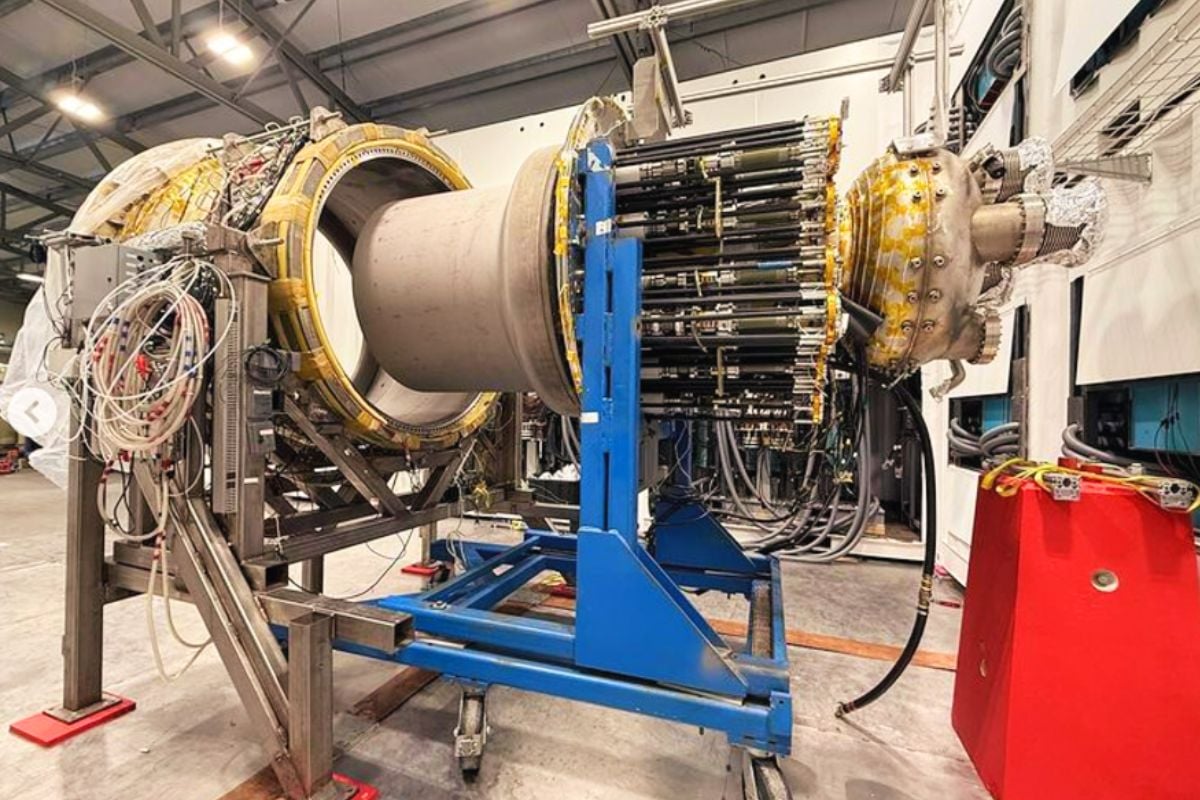

How magnetized target fusion works

General Fusion’s method, known as magnetized target fusion (MTF), forms a hot, magnetized plasma inside a spherical chamber. Around that chamber sits a swirling layer of liquid metal, which is rapidly compressed by an array of high-power pistons. The liquid metal acts like a dynamic, protective liner, collapsing inward to raise plasma pressure and temperature to fusion-relevant conditions. Because the event is pulsed, the system can achieve extreme compression without relying on ultra-costly superconducting magnets or complex, multi-beam lasers.

Plasma stability at extreme compression

In recent tests, the team reports a plasma density roughly 190 times the initial state, a figure that speaks to successful volumetric compression. Crucially, particle confinement time exceeded the compression time, a regime that supports stable heating and robust performance. The applied magnetic field was amplified by more than 13-fold, strengthening the cage that keeps the plasma hot and well-behaved. The outcome: a significant, repeatable neutron yield and growing evidence that the MTF recipe can be scaled with disciplined engineering.

From PCS experiments to LM26

The company’s Plasma Compression Science (PCS) experiments validated the concept of a collapsing liquid metal liner around a spherical tokamak configuration. According to the team, this marks the first time such a geometry has been compressed with a liner designed to implode in a controlled, symmetrical way. These results feed directly into the Lawson Machine 26 (LM26) program, a next-step platform built to test higher compression, longer confinement, and stronger coupling between the plasma and liner. If successful, LM26 aims to push yields higher and tighten the path to an eventual pilot plant.

Key performance markers

– Approximately 600 million fusion neutrons per second

– Plasma density increased by about 190× during compression

– Magnetic field amplified by more than 13× under implosion conditions

– Particle confinement time exceeded the compression period

– Collapsing liquid metal liner around a spherical tokamak-like target

What industry leaders are saying

“We have demonstrated the viability of a stable fusion process using our MTF approach, laying the foundation for our innovative LM26 project.” — Mike Donaldson, Senior Vice President of Technology Development at General Fusion

This measured confidence reflects more than two decades of iterative R&D, and a shift from small-scale physics to system-level integration. It also highlights that the most promising fusion routes may balance ambitious targets with pragmatic engineering tradeoffs.

Why the pulse matters

MTF’s pulsed nature offers several potential advantages. Short, intense compression events can create fusion-relevant conditions without continuous, high-stress operation of magnets or lasers. The liquid metal forms a neutron-absorbing blanket that protects internal components, enabling heat extraction and straightforward fuel recycling. Over time, such a system could be built for reliability and cost control, reducing maintenance and extending machine lifetimes. It is an architecture designed for manufacturability as much as for core physics.

Scientific context and next steps

As with all fusion claims, the central question is net energy—the point where output exceeds input with clear engineering margins. The current results, published in Nuclear Fusion, do not claim breakeven, but they do show high-yield, stable operation under carefully diagnosed compression. The next waypoint is LM26, which will target stronger coupling, higher pressures, and repeatable performance under power-plant-relevant constraints. The broader goal is a fusion core that can run at meaningful duty cycles with predictable cost per kilowatt-hour.

A credible path to clean power

General Fusion’s advances suggest a practical line through the thicket of fusion challenges. By leaning on mechanical compression and a protective liquid metal liner, the company avoids some of the most expensive and fragile plant components. If LM26 fulfills its promise, the result could be a compact, economical, and scalable fusion system. For policy makers and investors, the message is cautious but optimistic: with sustained support and disciplined execution, pulsed MTF could move from lab success to grid-ready generation.

Are we sure this fusion hype isn’t just another government-funded sci-fi fantasy?

Are we sure you’re not in the employ of the Fossil Fuel Industry?

Because making baseless claims IS their pattern.

Hey, remember when the Fossil Fuel rumor mill claimed that solar cells would never pay back the energy needed to make them?

In March 2025, General Fusion’s CEO noted that since 2019, the company had attracted $3 in private investment for every $1 of public investment from the Canadian government.

Governments contribute to General Fusion’s funding in the form of grants, investments, and sovereign wealth fund participation. Key government and quasi-government investors include:

Canadian Nuclear Laboratories (CNL): Invested CA$10 million in August 2024 to support the LM26 program.

Business Development Bank of Canada (BDC) Capital: Invested CA$10 million in August 2024 and participated in the August 2023 Series F round.

Government of Canada (Strategic Innovation Fund): Contributed CA$69 million via grants between 2019 and 2025. This included a CA$5 million top-up grant in December 2023.

Government of British Columbia: Provided a CA$5 million grant in August 2023.

GIC and Temasek (Singaporean Sovereign Wealth Funds): GIC and Temasek are major investors in the company and are ultimately controlled by the Government of Singapore.

The other 75% is private funding.

Why is this called a record? JET regularly produced much higher neutron rates than 6 x 10^8 neutrons/s reported here. The JET record was something like 5 X 10^18 neutrons/s, so 10 orders of magnitude more than here.

You are 100% correct. I was wondering the same thing. Is it to discredit the americans…again?

Good point. How much energy was used to get that yield in comparison to the neutron yield, was it also an 10 ordees of magnitude greater or was it comparable with that neutron rate?

Right, they are quite far away from actual fusion happening. In addition their pulsing approach means the actual process will pulse, fission… then fusion happens then wait until they need to pulse again for another round of fission, then fusion. Quite in effective. The real question is how do they claim that these neutrons will not escape that liquid metal layer therefore making this reactor more reliable than the other type like tokomak, etc.

What I can see is that when they can start the fusion process reliably, they maybe able to increase the compression to allow pulsing and with the help of lasers to start the next stage of fusion with He4 which will not generate neutrons but takes twice the temperature to start comparing with fusion using d+t.

This amount of neutrons is prima facie evidence of Fusion.

Were you under the impression that mere mechanical compression can create a flood of neutrons?

If that were so, my old truck would be creating neutrons every time the pistons fired.

Sounds like a number relative to the plasma mass. Most journalists wouldn’t understand the relevance.

Because this was CANADAS record. They dont ever do anytjing worthwhike since theyve gone communist. So they need something to make them seem relevant.

You planning an invasion again then, like you did to Poland? Maybe some concentration camps? Come try it! We’ll like up your captial just like last time!

You just discredited yourself.

The breakthrough was from the effectiveness of the MTF system and proving that it can actually work.

600 million neutrons? Cool, but are we ignoring the massive energy waste here?

This was a good article. Thanks!

600 million neutrons per second sounds scary, but fusion risks are way overblown compared to fossil fuels.

Wait, are we sure smashing neutron records actually means fusion is close or just hype?

One-time compression only? Or a repeatable event? How many implosions per second? How long before complete overhaul and cleaning?

Good lord Jackson, you sure have swallowed the company line. Might be nice if your editors ran this by a nuclear engineer first.

600 million neutrons per second? Feels more like sci-fi hype than real fusion progress.

Who knew Canada had smart people?

Another Activist-Journalist masquerading as a Particle Physisist. The Headline alone is misleading: “Shatters The Record…”: Heavy on Emperical Observation, Light on experimental details (Risk Levels, F Value, Data Sets, Test Method to ensure Random data selection, and a host of other boring details) that any real Scientist would have in place before making such boasts.

I would simply settle for the difference between the Energy Input vs Energy Output: If less than 0, this Article is patently false.

a typical NIF shot these days is 10 thousand million million million million neutrons per second….

Guys read the article before commenting. NIF and JET doesn’t use MTF; which this record is specific to.

And once again, controlled Fusion is just 5 years away. Just like it has been for the last 50 years… 🙄

Oh what our imperfect human brains are capable of is amazing. I refer to BOTH the engineering this article highlights, as well as the COMMENTS 😉

Tesla… It’s been done before in a different method